Fiber-Laser Cutting Machine is mostly used in the manufacturing industry for high-end and accurate metal cutting processes via strong laser beam techniques. It includes cutting metals like aluminum, brass, stainless steel, and many others.

We have tried to calculate running cost of 1.5 kw laser cutting machine. We have used 8 mm MS sheet and cut it using oxygen. we have considered all cost like manpower, electricity, consumable parts and oxygen consumption.

Cutting process and costs

For metal cutting, first we need to set the program like lead point, cooling point, oxygen bar, palette framing, and other parameters. Additionally, you can separately calculate the overall costing on the consumable, electricity, oxygen consumption, and manpower.

To calculate running cost of laser cutting machine we cut 8 mm SS using oxygen and measured various expenses. Here is summary of each expenses.

Manpower Cost: As you know laser cutting require helpers and operators. So we shall add hourly cost of helpers and operator. To operate machine efficiently you need one operator and 2 to 3 helpers. So we shall calculate hourly salary of 4 staff which shall come to around Rs 240 per hour. You can estimate as per manpower cost in your area.

Electricity consumption: For our experiment we concluded to cut 8 mm MS sheet. The machine used 6.5 unit of electricity. Let’s assume Rs 10 per unit the electricity cost comes to be Rs 65 per hour of cutting. Additionally, you can add costing as per your area.

Oxygen consumption: In the above MS cutting experiment we concluded that one oxygen cylinder can cut for slightly more than 3 hours. The price per cylinder is Rs 350. So hourly oxygen cost is Rs 120. You can calculate hourly oxygen cost as per your area.

Consumable parts: It is categorized between three parts, nozzle, protective lens, and ceramics.

- Nozzle: Nozzle helps in spraying over the sheets so that the cutting will be smooth. There are two types of nozzles: single spray nozzle(air or nitrogen base cutting), and double spray nozzle(oxygen-based cutting). So, it works on the spray base technology of nitrogen and oxygen beams on the metallic surface. And the nozzle and beam’s whole size differs between 0.8 mm, 1mm, 1.2 mm, 2.5 mm, 3 mm, 4 mm, and so on.

Working life: 200 hours- 400h (250 h average)

Associated cost: 450 rs / hourly rate 3rs

- Protective lens: It is also nitrogen and oxygen-based and helps in focusing the laser beam for the cutting of metal surfaces. And, it varies in size with the focal length of the lens. A nitrogen or air base cutting has a good lifespan compared to oxygen-based cutting. As the protector lens burns more easily and gets spots easily and oxygen spray laser does not cut smoothly.

Working life: 600h-1000h

Cost: Rs 1.25- Rs.1.5 per hour (total 750 )

- Ceramics: It is responsible for laser cutting, marking, and engraving. During the cutting, process damages can happen due to accidents, overheating of the metallic surface, and any other reasons.

Working life: 5 to 6 hrs. (900h – 1200h)

Cost: Rs 1200, hourly rates 1 Rs.

At last, for calculating the entire cutting process, we need to analyze all the parameters of the above-mentioned factors.

Summary of Cost

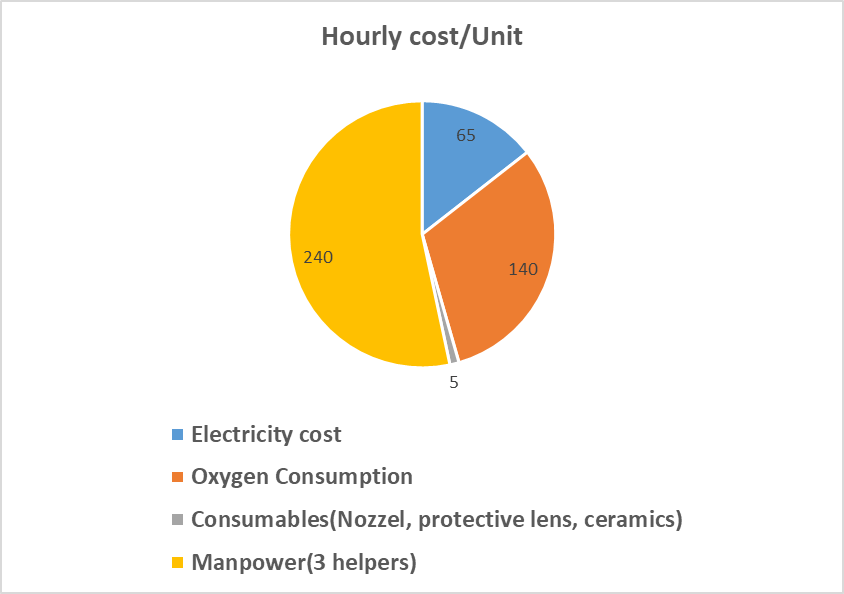

For easy of calculation we have summed up hourly cost in table below.

| Price distribution(per hour in Rs) | Units | Unit Cost | Total |

| Power consumption | 6.5 | 10 | Rs. 65 |

| Oxygen consumption | 1/3 Cylinder | 350 | Rs 120 |

| Manpower availability | 3 Helpers | 80 | 240 |

| Consumable | Misc | Misc | 5 |

| Total cost | Rs. 450/hour |

Summary of Running Cost

In short

The running cost of laser cutting machine is Rs 450/Hours. As clear from this study the major cost on running a metal laser cutting machine is manpower. While Oxygen/Gas cost is also significant. Other maintenance cost is less than 1% of total cost. The machine is hyped to consume lot of electricity or other consumables or maintenance. but it is all hype as evident by the study.

Also read this:

Reduce these mistakes to reduce cost further.

1. Damages caused during operational mistakes

Many operators needs formal operational training. As any mistakes can lead to products and parts damaged easily.

2. Wrong or inaccurate cutting frameworks

The fiber laser cutting machine needs proper dimensions and cutting parameters. As any measurement deformity can steadily affect the cutting settings and your whole cutting process may get affected. Further, the machinery parts get also damaged if it is not operated correctly.

3. Non-stop operations

If the fiber laser cutting machine is used for non-stop operations for industrial manufacturing of the final products. It can affect the equipment and reduces its working efficiency. Further, the parts get damaged easily.

More about metal laser cutting machine

Metal laser cutting machine is getting more and more popular in fabrication industry. It is commonly used by following industries.

- Metal Sheet Processing

- Aerospace parts cutting

- Electronics appliances

- Tube Fitting and cutting

- Automobile industries and spare parts

- Textile Machinery

- Elevators/Lifts

- Household Appliances

- Kitchen Utensils And Applications

- Craft Gifts

- Tool Processing and cutting needs.