A CO2 laser marking machine works on gases sealed tubal beam emission technology. And, it leaves precise and permanent marks over the non-metallic material surfaces. It includes mostly organic materials like plastics, ceramics, MDF, wood, glass, acrylic, etc. Further, we shall be discussing here the CO2 laser working mechanism and its deferential needs in industrialization.

Specification of CO2 Lasers

- Description-CO2 Laser

- Laser source power- 20W, 30W, 50W, 60W, 80W, 100W

- Wave length- 1060nm, 1030nm, 920nm

- Max linear marking speed-13000 mm/s

- Positioning method- Red focus, red preview

- Connection- USB, RS232, Ethernet

- Power supply- 220V, AC50/60HZ

- Application- Marking on bar code, text messages, batch, date(expiration, manufacturing, etc), LOGO, image, etc.,

- Best materials- Plastic, Acrylic, wood, paper, ceramics, glass, some metal

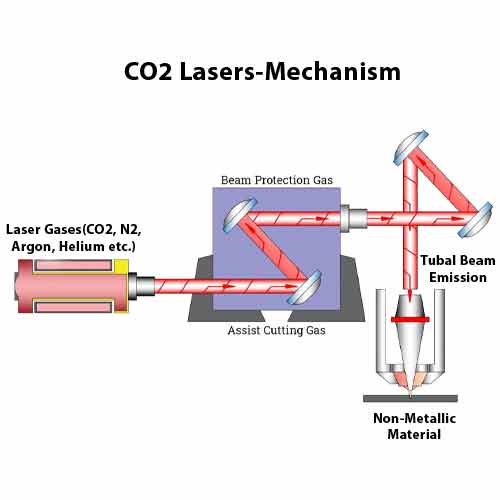

CO2 Lasers-Mechanism

A CO2 laser machine uses gaseous mixtures of (CO2, Argon, Nitrogen, helium, etc.) that passes through the narrow tubes. It emits a radiation wavelength of 10.6 μm that is absorbable by many materials. Now, once the beam’s emission falls on electrodes it creates electrical discharges. In addition, the final beam emission produces energy-efficient, high-precise, stable, and permanent marks over the material surfaces.

Moreover, it requires multiple power options, for more efficient results on marking, cutting, engraving, and intricate designing working operations.

Characteristics of CO2 Lasers

- A CO2 laser machine uses molecular gases (CO2, N2, and helium) mixtures for fine laser marking.

- It has a higher power output of 20w and onwards, to get better efficiency.

- The machine does intricate designing and markings on non-metallic material perfectly. However, the metallic marks are not that efficient.

- It has a wavelength range of 0.6μm and 10.6μm.

- Co2 lasers have inbuilt software support for controlling all operational activities.

Industrial Applications of CO2 Lasers

CO2 lasers are very effective in high-precise markings in non-metallic materials. So, it is highly demanding currently in many industrial applications:

- Food and Beverages Industries: CO2 lasers are very safe and effective ways of producing direct surface markings. It includes marking on fruits, vegetables, eggshells, meats, fish, etc. Moreover, in many beverage industries, packages mark serial codes and barcodes. In addition, product info like wine bottles, milk packets, juices, and similarly others.

- Gemstone markings: By using a 10.6 or 9.3-micron CO2 laser, the precious gemstone markings are done accurately and precisely. Additionally, you can see different marking and engraving patterns on opals, coral, Agate, jade, etc.

- Displays and panel-making industries: The LGP Backlight panels are highly sensitive materials that need very precise and damage-free markings on their smooth surfaces. So, a CO2 laser marking machine helps in marking needs like logos, text codes, etc.

- Automotive industry: In the automobile industry, the tools, and machinery are marked perfectly using the machine. It includes the decoration of upholstery, barcodes, logos, and engraving of codes. In addition, serial number, Intricate designing of the automobile parts made of plastics, metals, etc.

- The packaging industry: The material packets are marked using the machine. It prevents the counterfeiting of original products. Furthermore, it is quite helpful in logistics, and easy identification of the final products.

- Decoration Industry: Whether, there is a need for indoor and outdoor designings like hanging walls, watches, lighting decors, gates, furniture, or any other decorative items. A CO2 laser machine is the most preferred one.

Read More:

How a CO2 laser machine is a profitable choice?

Due to technological proliferation, the industrial final product’s diversification is also needed to enhance its final touch. So, here, a CO2 laser is technologically and cost-efficient to process further. Now, here are some of the valid points that describe better the CO2 laser marking machine’s profitability:

- Higher Efficiency and Speed: CO2 laser machines are typically faster and more efficient compared to traditional cutting methods. In addition, if you are expecting complex cuts, engravings, and etchings in limited timing, it is possible with this machine.

- Cost and Time Savings: A CO2 laser machine is very cost and time-efficient. However, you may have to invest initially to do the proper set-up, which includes relevant accessories, tools, manpower, and other factors. Moreover, CO2 laser machines have low maintenance requirements, minimizing downtime and repair costs.

- Customization and Personalization: In today’s market, customization and personalization are consumers’ choices. CO2 lasers help in engraving and precise marking for personalized designs on jewelry and promotional items. In addition, it enhances the branding and reliability of the product.

- Industrial Growing Demand: The demand for laser cutting and engraving services continues to grow across various industries. In addition, for industries’ growth and revenue management, the demand for CO2 laser services is expected to increase. However, for further recommendations see the usability preferences and budget to purchase the correct machine to reduce further losses in the future.

Overall, by going through the other industrial uses, you may define your required parameters and industrial needs to continue further with the machine. Moreover, you can easily choose your perfect machinery and get the results in more effective ways.