A high-tech fiber laser marking machine uses Q-switched fiber laser technology to enhance the beam emission quality. Its Q-switching technology is used to generate short, high-intensity pulses of laser light and it further gets stored into the laser cavity.

Additionally, Q-switched fiber laser devices are the main source of energy oscillators that come in different power outputs like 20W, 30W, 50W, and so on. Further, it helps in pulse energy conversion and refined marking, engraving, and cutting quality on metallic and non-metallic materials.

Q switched fiber laser- Overview

Price- TBD+GST

Call/or WhatsApp: 9804718718

Specification

- Usage/Application-Fiber laser marking machine

- Laser Type-Q switched fiber laser

- Brand-Raycus/Max/JPT

- Voltage-24 +/- 1

- Power-20W-30W-50W

- Power Consumption-200-300-400W

- Laser Wave Length-1064nm

- Temperature- 0-40 degree (working temp.)

- Cooling Mode- Air Cooling

- Accuracy- <=0.01 mm

- Dimensions- 1500*650*650mm Millimeter (mm)

- Central wavelength-1055-1070nw

- Bandwidth-<5nm

- Pulse energy-0.8mJ

- Repetition frequency rate-30-60KHZ

- Pulse width-100+-20ns

- Beam Quality-(M2)<1.5

How it works?

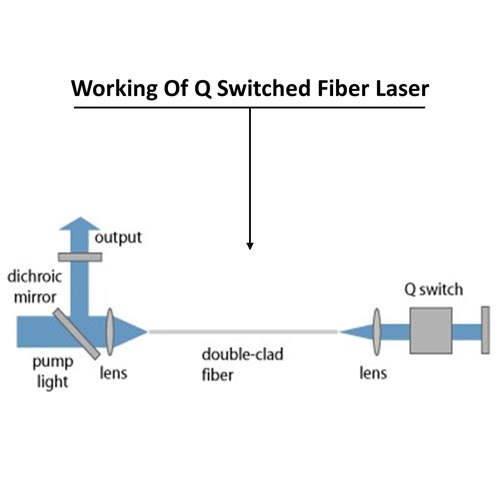

Q switched fiber laser working phenomenon is a little different in that utilizes a technique called Q-switching to generate short, high-intensity pulses of laser light. Here is the working process of a Q-switched fiber laser.

- Higher-Repetition Rate: Q-switched fiber lasers can operate at high repetition rates, and enable a high average power output.

- Pumping: The gain medium is pumped with an external light source, using a laser diode. The pumping process energizes the atoms in the gain medium, preparing them for laser beam emission via the lens.

- Pulse Generation: The sudden drop in cavity loss causes a rapid build-up of stimulated emission, resulting in a high-intensity laser pulse. The pulse duration is typically in the nanosecond to picosecond range, depending on the specific design of the laser.

Application

- Laser application: It includes laser marking, laser drilling, laser cutting, etc. So, it is widely used in multi-industrial applications.

- LIDAR application: LIDAR technology helps in the car industry, aviation sectors, security surveillance and many others to detect the 3-dimensional images of the surrounding.

- Medical Application: It is used in multiapplication in medical industries. It includes tattoo removal and other dermatology application.

- Derusting over the metallic surfaces: If a metallic surface gets affected by rust, the unit is removed using laser beams. And, it also, helps in surface treatments as well.

- Metal surface applications: It includes processing of metal surfaces like Peeling, coating, etc.

Advantages

A high-tech Q-switched fiber laser has many advantages over laser applications because of its inbuilt features. And, few of its listed advantages are shown here:

- Compact in size: Due to its compactness, it can be placed anywhere in the process of operations. And, it is easy to handle as well so can be replaced at the destined operational limited spaces.

- Higher energy pulses: Due to the higher energy pulses rate, helps in efficiency and high-precision material processing. It includes micromachining, engraving, cuttings, and drilling,

- Stability and Reliability: Q-switched fiber lasers are known for their stability and reliability. Machines’ inbuilt specifications are responsible for their continuous operations. This makes them suitable for industrial applications that require consistent and reliable laser output.

- Higher pulses repetitions rate: It produces higher pulse rates, and is responsible for multi-operations in less processing time.

Disadvantage

- Higher-cost: Q-switched fiber lasers cost litter higher because of their advanced technology and high-quality components. However, the cost has been decreasing over time with advancements in fiber laser technology and increased availability.

- Complexity to the laser system: Q-switched fiber lasers have a more complex design as compared to the other fiber lasers.

- Proper Cooling management: Due to thermal dissipation, it requires proper power thermal management.

- Limited Wavelength Range: Q-switched fiber lasers are typically designed to operate at specific wavelengths, such as around 1 μm (micrometer) or 1.5 μm. While these wavelengths are suitable for many industrial applications, they may not be optimal for applications that require different wavelengths.

Q switched fiber laser verses Continuous fiber laser

| Q switched fiber laser | Continuous fiber laser | |

| Nature of Energy | pulses of energy | measured in watt |

| Type of medium used | laser emission | gas, dye, solid state or excimer |

| Featured qualities | Highly stable laser output High single-pulse energy High marking efficiency Short pulse setup time High reliability Less- Maintenance | Highly- Efficient Gratings Robust Optical Cavity Compact designed High Power output Fine Beam Quality Reliable and durable machine |

| Price | Little expensive than fiber lasers | Less expensive the Q-Fiber technology |

At last, you can easily identify the noticeable difference between the two laser fiber sources. And, for further clarification, you can go through the fiber laser machines. As well well, you can connect us @Call/or WhatsApp: 9804718718