Hindcam manufactures high-quality CO2 laser-cutting machines. This machine is also called an acrylic laser cutting machine or a non-metal laser cutting machine. The CO2 laser beam’s tubal emissions of gasses (carbon dioxide, nitrogen, hydrogen, and helium.) pass to cut over non-metallic surfaces. It includes wood, acrylic, MDF, PVC, leather, etc.

Machine’s Specifications

60-Watt CO2-laser-cutting- machine

Cutting Area: 2×1.5 Feet over the non-metallic surfaces.

Application: gift, plastic, wood, MDF material cutting.

Operating software: RDworks

Price (60 watt): Rs 230000 + GST

Call or WhatsApp: 9804718718

80-Watt CO2-laser-cutting- machine

Cutting Area: 2×3 Feet over the non-metallic surfaces.

Application: gift, plastic, wood, MDF material cutting.

CAD software: EZCAD

Price (80 watt): Rs 265000 + GST

Call or WhatsApp: 9804718718

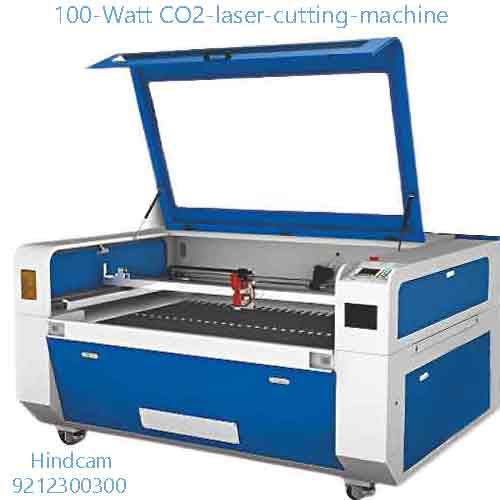

100-Watt CO2-laser-cutting- machine

Cutting Area: 3×4 Feet over the non-metallic surfaces.

Application: gift, plastic, wood, MDF material cutting.

CAD software: EZCAD

Price (100 watt): Rs 290000 + GST

Call or WhatsApp: 9804718718

130-Watt CO2-laser-cutting-machine

Cutting Area: 4×8 Feet over the non-metallic surfaces.

Application: gift, plastic, wood, MDF material cutting.

CAD software: EZCAD

Price (130-150 watt): TBD + GST

Call or WhatsApp: 9804718718

Best Fit Materials

- MDF: Best and damages-free cutting using CO2 cutting lasers.

- Acrylic: All acyclic products cutting through CO2 laser cutting machine.

- Leathers: Make industrial cutting on leather products.

- Wood: For precise cuts of wood using this machine.

- Plastic: Make the perfect designs and cuts on plastic materials, gifts, etc.

- Glass: All kinds of glassy materials cutting.

Applications

- Acrylic cutting and engraving: Acrylic is the perfect material for CO2 laser cutting. The cutting quality is very fine. And for high cutting thickness over the acrylic, you can use CO2 laser cutting machines. Acrylic can also be engraved very rapidly. Acrylic laser cutting is employed in decorative items, signage, interior decoration, etc. Due to its special application in acrylic cutting, the CO2 laser cutting machine is also called the acrylic laser cutting machine..

- Shoe upper laser cutting: Non-metal laser cutting with a projector is suitable for the shoe industry. Sports shoes made using the knitting process can be easily cut. Lather shoe uppers soles is made using our CO2 laser cutting machine.

- leather and Rexine: Leather and Rexine shoes and ladies purses designs created using CO2 laser cutting machines.

- Plastic cutting: Almost all plastics cut and engraved using a non-metal laser cutting machine.

- Wood and MDF: You can cut wood and MDF precisely for the non-metal with the laser cutting machine. The applications are decorative items, educational items, and stencils of various types.

- Wedding cards and paper cutting: You must have seen decorative wedding cards and other cards with special designs cut on the paper. This uses CO2 laser cutting machine.

- Decorative items and gift items: If you are producing decorative items, then a CO2 laser cutting machine is a must for you. It can produce endless designs of decorative items using various materials.

- Granite: limited application for engraving. Granite engraving using a CO2 laser cutting machine is perfect. However, it needs a finishing touch afterward.

- Not suitable for: The CO2 laser cutting machine is not suitable for glass, stone, rocks, PCB (hard PCB), and metals.

Key Features

A CO2-laser machine is like a boon for non-metallic precise cutting for industrial uses. Additionally, the machine is compact and easy to handle. Here are some points for the CO2 laser cutting machine:

- Great Flexibility: The machine has inbuilt tool set-ups that manage the cutting area and material thickness. In addition, it is easy to operate on any non-metallic materials without damaging the surfaces.

- Compact in size: The machine’s body is as space availability and looks very compact.

- Accuracy and Precision: Laser cutting machines have higher accuracy depending on the cutting material type. And, due to precise cutting, the final products look aesthetically appealing.

- Higher Speed: The high-tech laser cutting machine is faster than the traditional hand-held cutting machines.

- Fully-Automated: The machine is provided with automated software to run the process in an automatic way.

- Reduces manpower and costs: Due to automation, it reduces manpower and maintenance costs.

Limitation of CO2-Laser Cutting Machine

Although, CO2-laser cutting machine has many advantages, but still it lacks in certain aspects. Find below some important limitations:

- Material thickness: It is not suitable for thick materials, hence the cutting quality may suffer.

- Noxious vapors and gases emission: Due to multi-functionality and operations, the emission of noxious gasses is quite common.

- High levels of energy use: It uses higher power output for tubal emission of gasses like carbon dioxide, nitrogen, hydrogen, helium, etc.

- Higher upfront expenses: The initial investment is higher.

Warranty and Services

- 1 year of onsite-warranty provided.

- Free installation with machinery maintenance.

- Free online training on the products.

- Call/WhatsApp: 9212300300

Samples of CO2-Laser Cutting

Image-1

Image-2

Image-3

Watch the Video

Frequently Asked Questions

Q1. What is the lifespan of a CO2 laser cutting machine?

Co2 laser tubes have a lifetime working efficiency. However, you can expect its operational working duration to be somewhere around 1 000–10 000 hours.

Q2. Can a CO2 laser machine cut a mirror?

Well, it is not to laser cut glass with CO2 laser machines. You can use a handheld cutter that perfectly fits the cutting size. However, thin surfaces of glass materials is easy to get cut using the machine.

Q3. Which laser cutting machine would be good for wood and acrylic material cutting needs?

Although, you can use fiber and UV lasers for cutting on non-metallic surfaces, However, for greater accuracy, a CO2 laser cutting machine is most recommended.

Q4. How much power output of a CO2 laser cutting machine is recommended for precise cutting?

It is recommended to buy CO2 lasers above 60 W for a more efficient result.