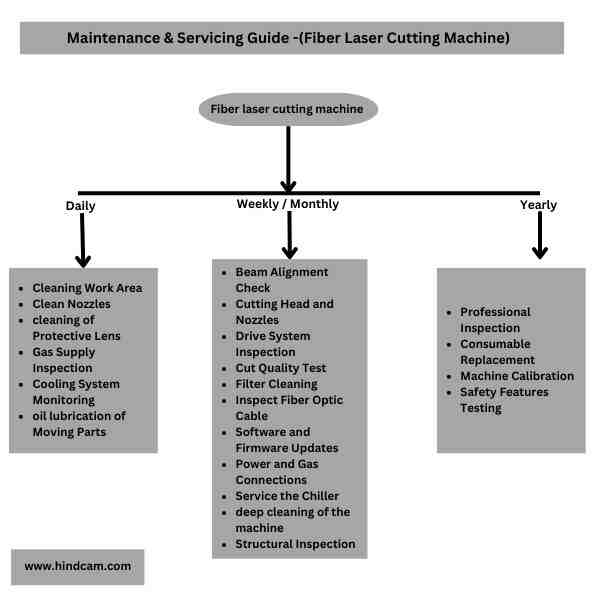

A fiber laser cutting machine has very critical components that needs to go through the regular maintenance and servicing time to time. As this enhances the working efficiency and reduces the future damaged possibilities and also increase the lifespan of the machine.

Step-wise servicing of the laser cutting machine components

Here are some of tips for the repeated cleaning and servicing of the laser component for the better efficiency and long-lifespan of the machine.

1 . Water chiller service:

a. Check for the correct working voltage and hertz. Additionally, whether its stabilizer wires are proper or not. Also to ensure that ground earthing is correctly done to avoid any electric shock and fire in the future.

b. replacement of the antifreeze once the temperature falls below 0°C, and the working environment temperature should be within 40°C.

c. Check that the air inlet duct and air outlet duct are unblocked. The fan should not be blocked within 500 mm. and the dust-proof net should not be blocked within 300 mm.

d. Check for the water filler level at its good level (not below or overfilled). And do not use a circulating. Check for the E6 alarm always.

e. Air inlets regular cleaning, once a week improves its working.

f. Chiller water should be filled with clean water and replaced every 2 months and drained accordingly.

Moreover, the temperature set as per the weather changes. Lastly, the pipeline should be checked and cleaned. It also needs fan cleaning repeatedly in the inlet and outlet.

2. Lens and nozzles cleaning: Lens and nozzles are the crucial parameters to check on a regular basis. This might affect the cutting quality, damage the machine’s laser head and affect its cutting efficiency. To start the cleaning process, we must eject the lens and the nozzle very carefully after the machine has been shut down and cooled. A lens should be checked for any kind of dust, metal splatter and cleaned properly using alcohol/isopropyl alcohol. With the gentle touch of skimmed cotton wool/professional lens wipes. Additionally, nozzles repeatedly checking(clogs etc) improves proper gas flow.

3. Cleaning of condenser unit: Condenser unit prevents the overheating issues during the machine’s workflow via air blowing/pressure to the s&a chiller. In addition, it also increases the machine’s working efficiency. Here are some of the useful steps to follow for the condenser unit cleaning process:

a. Check and remove any kind of dust, dirt, or debris from the condenser coils or fins.

b. We can also remove its dust/dirt by blowing of compressed air.

c. We can remove the oil/paints or any other debris using a soft brush.

d. we need to ensure for any kind of blockage to its airflow followed by debris/dust/other components.

4. Periodic lubrication of the moving parts : We need to do a periodic inspection, cleaning and oil lubrication of guide rail, ball screw system and other applicable moving parts. As presence of any kind of debris can drastically affect its moving parts movement and high-precision working mechanism.

5. Cleaning of laser cutting head: We also have to regularly do the cleaning of the laser cutting head, nozzles, connecting cables, and protective windows.

read more:

6. Latest software& Firmware updates: A regular firmware and software updates enhances its optimal performance and to get into its latest features. And for its smooth functioning by using a command of “FirmwareUpdate.exe” with its explorer. And after the installation, we must re-verify by running the machine to check its latest features working proficiency.

Here, we can download the latest version(6.3.765.10 for FSCUT2000C) via the Cypcut website by following the below steps.

a. Latest Download Updates: By visiting the official CypCut website, we can download the latest software and firmware version(“FirmwareUpdate.exe”) for the required setup

b. Easy Software Installation: Run the installation file to update or install the CypCut software on your computer.

c. Transfer Firmware: Copy the firmware file to a USB drive or connect your laser cutter to your computer.

d. Update Firmware: Open CypCut software, navigate to the settings, and select “Firmware Update” to upload the new firmware to the machine.

e. Restart: Reboot the machine to apply changes and confirm functionality.

7. Check Electrical Components:

- Inspect electrical connections and power supplies for wear or damage.

- Tighten any loose connections and replace faulty components.

8. Laser Tube Maintenance:

- Monitor the laser tube for performance and replace it when necessary.

- Clean or replace the water cooling system to avoid overheating.

9. Inspection and cleaning of Exhaust/ventilation System:

We need to make sure that the laser cutting machine is running under proper ventilated space/area. In addition all the exhaust fan and ventilation system are working properly to remove fumes and smoke that is generated during its operational process.

FAQ- Laser Cutting Machine Maintenance

Q1. Why is the machine not starting?

If the machine does not start, we should check for its power supply (3 phase), 24DC power>sensor>card> transferable to other medium.

Q2. Why the laser cutting machine have bad cutting quality?

We should expect accurate and good quality once the parameters should be correct. It includes design+speed+focus+power. Additionally, the red pointer should be placed and checked with the correct sheet alignment.

Q3. Why your machine’s not working properly?

We should check for the proper maintenance of the wire for any kind of cuts/damages caused by the presence of rats and by any other reasons. Also, whether it is attached with the machine at correct points.

Q4. How to check for the sensors?

We need to check for the sensors, whether they are working properly in the X, Y, and Z axes, and they should be immediately replaced in case of any working defaults. Additionally, any kind of dust/moisture can affect its working efficiency. And it shows an alarm on its screen on the BCS-100.