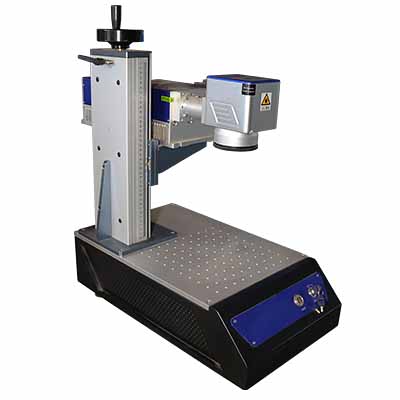

An advanced flying laser marking machine, CNF160, is designed for continuous marking. It is widely used in the production line marking over the numerous metals, plastics, and similar materials. It leaves high-precision and permanent markings over the materials. When it is placed over the moving belt underneath the red pointer marker via the laser beam. Additionally, you can easily manage the marking needed for the text, logo, batch code, and other info by creating it over EZCAD software via its touch panel.

Machine’s Overview

- Laser Type: Fiber laser (20W, 30W, or 50W)

- Marking Speed: 60 m/s

- Marking Area: 160 x 160 mm or customizable

- Laser Wavelength: 1064 nm

- Laser Source: Fiber laser

- Frequency– 20khz-500khz

- Marking Precision: ±0.01 mm

- Min Line Width: 0.01 mm

- Min Character Height: 0.2 mm

- Cooling System: Air-cooled/water-cooled

- Power Supply: 220V ±10%, 50/60Hz

- Control System: Digital controller with real-time processing

- Software Compatibility: (CorelDRAW, AutoCAD, and other vector graphic programs)

- Material Compatibility: Metals, plastics, ceramics, glass, coatings, and more

- Application: production (batch code, text, logo, designs)

Starting Price: Rs TBD+GST

Call/Whatsapp 8595648467

Features

A flying laser marking machine uses fully automatic and advanced laser beam marking technology. It has a streamlined workflow using conveyor belts and sensor integration that helps in continuous laser marking over metallic and non-metallic products. Now, here we shall be describing the major features of a flying laser marking machine:

- Streamlined conveyor system: A flying laser marking machine has an automated conveyor system that helps in fast and continuous laser marking production. Through its moving belt, the marking materials—plastics, metals, and glass—can be kept in line for mass laser making.

- Cost and time-savvy marking: All the laser marking is done by placing the material over its moving conveyor belt. So, this saves time and the cost of unnecessarily handling it every time. This reduces the labor and electricity costs during its marking operations.

- Touch Control Panel: It is connected to the touch control panel, where the marking parameters like logo, product details, designs, and more can be set to give the final laser marking command. It has the latest software control that supports EZCAD, Coral Draw, and other supported formats.

- High laser marking speed and precision: It has a high-speed laser marking with a laser marking precision of ±0.01 mm.

- High material marking coverage: This machine supports different material laser markings like glass, plastics, metals, non-metals, and much more. And leaves high-precision and clear marking on its surfaces.

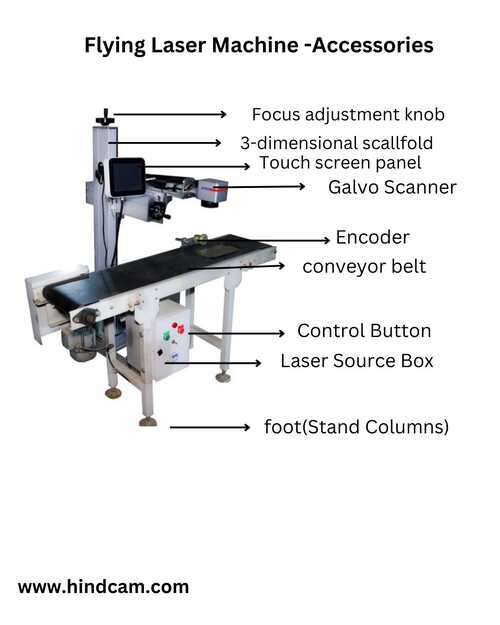

Accessories: Flying Laser Marking Machine

A flying laser marking machine consists of these following accessories:

- Encoder: An encoder helps in controlling the correct laser marking speed, position, and direction of the moving objects. And it has a connection with the conveyor belt.

- Ground wire: It has a connection with all the electric components. The grounding wires ensure any kind of shock, accident, or damage.

- Hexagonal wrench: It helps in driving and fixing bolts and crews.

- USB disk and training videos: You can connect the UBS for the transfer of designs, file formats, and other manuals to control the marking precision and smooth workflows.

- Bracket: It is provided to mount any components safely.

- Touch-screen control system: An automated touch-screen control panel system helps in setting the marking parameters and high-precision laser marking.

- Photoelectric switch: It is a very important part that detects the object via the laser beams

- Power cable: A power cable is provided with the machine for its compatible electrical

So first of all, to get the machine powered on, we need to connect the power cable and supply, and then the sensors and encoders are connected to the conveyor belt of the production line. Then it is followed by the ground wire connection and photoelectric switch connection. Additionally, once all connections are completed, we must check for the functionality test of the machine by switching it on. Finally, the laser marking parameter is set up over its touchscreen panel and sends the final marking command.

Application

A flying laser marking machine is best for the multiple industries for permanent and high-precision bulk marking. It includes texts, symbols, designs, batch codes, serial numbers, manufacturing/expiration dates and patterns, bar codes, 2D bar codes, and much more. Here are some of the major applications:

- Cann and bottle marking: Any production line marking over PET, HDPE, plastics, glass, and aluminum is easy and fast using this non-contact method. It highlights the company logo and product details like quantity, weight, expiration dates, manufacturing dates, bar codes, etc.

- Wire and cable marking: It leaves clear, permanent, and high-precise laser marking on different wires and cables made of metal and non-metal.

- Wood furniture: It is good for all categories of wood plates, furniture marking, and designing.

- Glass designing & marking: Complex designing and printing over the wine bottles, mirrors, and vehicle mirrors.

- Plastic materials: Any plastic-made product marked with a flyer laser marker leaves clear marking.

- Eggshells: All kinds of detailed marking over the eggshells are managed for fast and efficient laser marking. It describes selling by date, production date, serial numbers, barcodes, etc.

- Electronic components: These include wires, fuse, resistors, capacitors, circuits, switches, MCB, and RCB all kinds of high-end small electrical components are laser marked using this technology.

- Medicine tin foil: all kinds of pharmaceutical pieces of equipment and tin foil laser marking is done via the fast laser beam. It prints the product details like name, expiration dates, manufacturing date, quantity, and much more.

- Nameplates & Signboards: A flying laser marking over nameplates, made up of SS, aluminum, brass, plastics, PVC, and many others.

- Ceramics products: We can get a clear and precise marking over the numerous ceramic-based products, the pots, plates, cups, ceramic scenery, ceramic tiles, and sanitary wire.

- Leather products marking: It is also widely used for leather products marking purses, wallets, keychains, nameplates, shoes, and much more. It includes bar codes, brand names, logos, etc.

Flying Laser marking machine verses Fiber laser marking machine

A flying laser marking machine and a fiber laser marking machine both use the laser beam technology for the laser marking. However, there are many pointable differences that describe its working functionalities. Here we shall be going through all those points for better clarity.

| Features | Flying Laser Marking Machine | Fiber Laser Marking Machine |

|---|---|---|

| Laser Source | Can use fiber laser, CO2, or UV laser | Fiber laser |

| Operation Type | High-speed marking on moving objects | Can be used for stationary or automated setups |

| Speed | Very high-speed, suitable for production lines | Fast speed depends on material and thickness |

| Automation | Fully-Automatic | Semi-automatic |

| Synchronization | Uses encoders and sensors | managed via control panel |

| Material Compatibility | Metals, plastics, paper, ceramics | Recommended for various industries (metallic marking—designs, logo, nameplates, etc.) |

| Precision | High precision | Extremely high precision |

| Main Components | Galvo scanner, encoder, conveyor belt, laser source | Control system, Galvo scanner, laser beam source, workpiece table, laser source |

| Cost | higher | lower |

| Application | Recommended for various industries (metallic marking—designs, logos, nameplates, etc.) | All metals, plastics, and ceramics |

Frequently Asked Questions

Q1. Is this machine capable of marking complex designs?

Yes, we can easily customize the complex design via its supported software programs to make and implement the design over the marking materials.

Q2. What is the best buy price for this machine?

For the best buy price, you may connect to our sales team @ 8595648467.

Q3. What accessories do you provide with this machine?

You get the accessories with the fly laser marking machines. It includes an encoder, ground wire connector, photoelectric switch, converoyor belt, USB connectors, user manual, Galvo scanner, brackets, and foot pedal.

Q4. What are the possible limitations with this machine?

This machine does not leave a good effect on the static marking. However, we can widely expect exceptional results for the product marking details like serial number, QR codes, etc.

Other Recommendation