A CNC router is a multi-tasking machine, which can perfectly and precisely do cutting, carving, engraving, and shaping of various materials made up of non-metallic (wood, plastic) and metallic surfaces(stainless steel, aluminum, etc.). A CNC router with a vacuum table is a computer numerical control (CNC) machine that utilizes a table with an inbuilt vacuum system that holds the material surfaces during its routing operations.

Machine’s Overview

Price- TBD+GST

Call/or WhatsApp: 9804718718

Specifications

- Spindle Power-6 kW

- Standard sizes- 5” x 6” to 72” x 144”/ thickness(1 3/16” to 1.5”).

- X-Y Axis Working Area-1300 x 2500 mm

- Z Axis Working Area-300 mm

- Spindle Speed-18000 RPM

- Travelling Area 1570mm x 3100mm x 200mm

- Table material- wood, MDF, plastics

- Repositioning Accuracy- <0.3 mm

- X-Y Movement-Rack & Pinion

- Z Movement-Ball Screw

- Driven Motor-Stepper Motor

- Country of Origin- Made in India

Advantages of the Vacuum table

- Precise and repeatable machining operations: The CNC machine and a vacuum table brings more proficiency on precise cutting of the material surfaces cutting. With higher cutting friction and repeatable machining operation with the help of dual spindles.

- Reduction in material distortion: It also reduces distortion of material surfaces during the multi-operations.

- Elimination of clamps, and chucks: The extra clamps and chucks is eliminated using the machine.

- Increases productivity and waste reductions: A vacuum fixture is very helpful in increasing the machine’s productivity and reduces external clamps. In addition, it significantly reduces the material surfaces cutting wastes. So, the business can be profitable for a long run of time.

- Computer-controlled Operations: CNC laser machine is using the EZCAD software and other high-tech software programming. So, for the vacuum table works and its positioning. There will not be any issues further conducted.

- Higher-cutting Precision: It is helpful in higher-cutting precision of the edges.

- Multi-industrial application: The machine has multi-industrial applications. It includes wood-making industries, construction, indoor and outdoor units, aviation industries etc.

When to choose vacuum table?

A CNC machine uses the vacuum table for the correct positioning over the flat surfaces. As, vacuum table or vacuum chuck technology holds the materials for precise and perfection of cuttings needs. Here are some of the operational requirements, which a vacuum table uses for:

Precise Woodworking: You can go for the woodworking multi-tasks like milling, engraving, cutting, or sanding large wooden panels. This also helps in deformity-free smooth cutting precision on woody material surfaces.

Fabrication of material: The material gets more strength via it’s laminations, bonding, or gluing. Hence, the vacuum table can enhance the material fabrication through its smooth process.

Electronics parts assembling and modification: The small electrical parts can be assembled firmly using the vacuum table. It includes the soldering, component placements, etc. over the electrical parts assembling, like MCB panels, circuits, etc.

However, it has multi-application uses, but still, we can figure out the use of the vacuum table with CNC routers as per your usability and preferences of material used for it.

Read more:

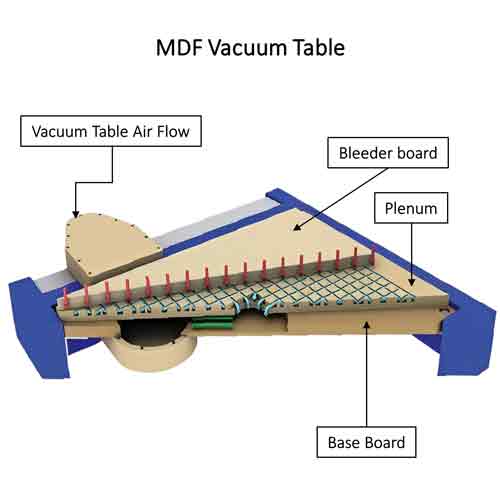

How vacuum table works?

The vacuum table(MDF) is a flat porous surface(small holes or channels) distributed across its surface. An MDF vacuum table consists of a plenum board and a bleeder board. All, the fixtures help in high- air streams to pass through the pores of MDF material, and by using the activated vacuum, it creates suction through these holes. And due to the atmospheric pressure, the machine creates cutting frictions.

Further, the final cutting precision over the material used placed on the vacuum table will be more accurate and without any deformity.

Limitations of the Vacuum Table

- Some parts could not be covered for the vacuum to hold them.

- The pump runs perfectly only on a plain and smooth table surface.

- It has a limitation of (13-14 lbs) of downward clamping force/square inch.

Important Parts- Add-ons

Here are some of the name of important add on parts that you can go for the higher cutting precison with a CNC machine.

| 1. A CNC router for drilling, holes and cutting works. |

| 2. 4th Axis Rotary |

| 3. 3x pieces of MDF |

| 4. Coolant System: Required for high-pressurized air streams for great cutting results. |

| 5. Dovetail Fixture: It helps in finger joints between the surfaces. |

| 6. Pen Attachment: It is used to mark on the surfaces using a pen like incision. |

| 7. A vacuum cleaner / vacuum pump: It has inbuilt inlet filters. |

| 8. Oscillating Knife System: It provides fine edges cuttings of the materials used. |

| 9. A vacuum adaptor: Used for distillation set-up |

| 10. Elevation Pods: For horizontal drilling and routing |

| 11. Dual Spindle- It reduces set up time and handling. |

| 12. Toggle Clamps- required for tool -free clamping |

| 13. Collat: It is helpful in gripping force during the operations, using the collat chucks |

| 14. Tool bit- an appropriate tooling kit helps in multi-applications |

Overall, a CNC router with a vacuum table provides a high-precision, reliable, and time and cost-efficient solution. For the perfection of the workpiece fixation during CNC routing operations. In addition, it enhances precision and productivity in various manufacturing and woodworking applications and reduces final wastage. Hence, for further queries on the vacuum table and CNC working phenomenon, you can reach us at @CNC router machines. Also, you can take a call to the technical and sales team on Call/or WhatsApp: 9804718718.

Frequently Asked Questions

Q1. How much flat surface is needed for the vacuum table?

The top flat surface of the vacuum table would be within .001″ per linear foot.

Q2. What materials are used for the vacuum table?

It can be made up of wood, MDF, plastics, metal, and many others. However, MDF has good porous nature material. And, it has a commercial use for the final precision cutting.

Q3. What is the price of a CNC router with a vacuum table?

You can get the final pricing of an MDF-based vacuum table @(TBD+GST). For further queries, you can contact us by Call/or WhatsApp: 9804718718.

Q4. Which technology a vacuum table uses?

It uses diffusion of gases technology. It includes adsorption, condensation, sublimation, ionisation, etc. for creating high-gas pressure over the material surfaces for cutting precision.