A CNC router machine is a high-end machine that uses its components (spindle, Cutting Bed, CNC Controller, Motion Systems) for its work. It also uses dual spindle power Servo motors– 3.5KW(Steppers Motor), and 6.5KW(Hybrid Motors). In addition, it is beneficial for enhancing the working efficiency of the machine’s operations. Further, the cutting works will come out with utmost precision, higher- accuracy, and without any deformity up to the specified area.

Machine’s Overview

Servo Motors(3.5KW)

Price: TBD +GST

Call/or WhatsApp: 9804718718

SPECIFICATIONS

- Spindle Power- 3.5KW

- Working Area -1300*2500*300mm

- Operating system- RichAuto

- Max. moving speed- 10000mm/min

- Reposition accuracy -<0.05mm/300mm

- Max. engraving speed- 6000-18000 rpm

- Motor CW -stepper motor

- Guide rail- Hiwin Square linear rail

- Working voltage- AC 220V/380V

- Platform- Aluminum

- Machine size- 3000*2000*2000mm

- Feeding height 300mm

- Engraving Instruction HPGL, G-code

- Drive- Stepper Drive

Servo Motors(6.5KW)

SPECIFICATIONS

- Spindle Power- 6.5KW

- Working Area- 1300*2500*300mm

- Operating system -RichAuto

- Max. moving speed- 10000mm/min

- Reposition accuracy-<0.05mm/300mm

- Max. engraving speed-6000-18000 rpm

- Motor Easy- Servo motor

- Guide rail- Hiwin Square linear rail

- Working voltage -AC 220V/380V

- Platform- Aluminum

- Cross- Beam Steel

- Machine size- 3000*2000*2000mm

- Feeding height- 300mm

- Engraving Instruction- HPGL, G-code

- Drive- Easy Servo Drive

Advantages of Servo Motor

- Higher- efficiency: The servo motors can efficiently work for many years.

- Compact in size: The servo motor is very compact in size and can be handled easily.

- Reliability: The higher-reliability of servo motors makes it more demanding. In addition, is more prominent in CNC operations.

- High ratio of torque to inertia: Higher torque ratio is directly proportional to acceleration of machine. So here you will be getting more working efficiency .

- Higher-accuracy: Using the high- power servo motor, greater working accuracy could be maintained.

- Great Torque control: Servo motors has great torque controls. In addition, it ranges approx. between (0,5 to 10 kg/cm).

- Smooth running during operation: Servo motors is helpful in smoother and error-free continuous operations.

- Less-Noisy workings: The servo motors is less- noisy and work very quietly. Hence, it can work very efficiently for non-stop operations noise-less.

- Higher- acceleration: It has higher acceleration of servo in units of (0.25 μs) / (10 ms) / (80 ms)

- High-speed performance: It has high-speed performance during the entire operations that includes cutting, engraving and other needs.

- Closed-loop control: A servo motor can efficiently detect feedback cycle, error, required correction. In addition, it collectively helps in closed-loop control.

Disadvantages of Servo Motor

Although, a servo motor plays an important role in machine’s working efficiency. However, it has some of its drawbacks in a loop. In addition, below-listed points can be easily identified using the Servo motors.

- Higher investments: You may have to invest a little higher initially.

- Vibrant in nature: Even though the entire operation is stopped, the servo motor still vibrates due to its back-and-forth one pulse. As a result, this may be irritating and not easy to handle for some time.

Also Read This:

When to choose router with servo motor?

A CNC router machine is used in multi-industrial applications for higher-cutting accuracy like aviation, manufacturing, construction works etc. And, once you use a Servo motor with a router, it drastically enhances its cutting precision, and high-torque and speed value to get the higher accuracy of work. Here are a few situations when selecting a router with a servo motor might be appropriate:

- CNC (Computer Numerical Control) Routing: CNC routers rely on servo motors for precise control of the router’s movement. They are commonly used in industries such as woodworking, metalworking, and plastic fabrication. Further, Servo motors offer high positioning accuracy, allowing for intricate cuts, complex patterns, and precise shaping.

- High-speed and High-precision Routing: If you require exceptionally high speeds and accuracy in your routing tasks, a servo motor-equipped router can be beneficial. Moreover, Servo motors provide rapid response times, which enable faster cutting speeds without sacrificing precision. This is particularly valuable in industries like aerospace, automotive, and electronics manufacturing.

- Automation and Repetitive Tasks: Servo motors are often employed in routers used for automation and repetitive tasks. Moreover, these motors can be programmed to follow precise paths repeatedly, making them suitable for mass production. In addition, assembly lines, and industrial processes that require consistent and repetitive routing operations.

- Variable Load Applications: Servo motors excel in situations where the load on the router can vary. In addition, they can dynamically adjust the torque output to maintain accurate positioning and prevent stalling or loss of control. This adaptability is valuable when working with different materials or varying cutting depths.

- Customization and Prototyping: If you’re involved in prototyping or small-scale production that involves frequent design changes, a router with a servo motor can be advantageous. In addition, the precise control offered by servo motors enables the creation of intricate designs. Further, it helps in customization with ease.

It’s important to note that routers with servo motors are typically more expensive than those with simpler motor systems. Therefore, it’s essential to assess your specific requirements, considering factors such as precision, speed, automation needs, and budget, before choosing a router with a servo motor.

Why Servo Motors are Used in CNC Machines?

A CNC machine using a Servo motor can work faster, more efficiently, and with more focused axis controls. In addition, if you are looking for higher precision and quality of work a servo motor can increase the torque control, high acceleration, and stability of work. Moreover, the cutting material will have smoother working efficiency and geometrically more focused at the specified cutting area over the cutting bed. So, here are some of the points, where servo motors are used in CNC machines.

1. More-Precise Movement

Similarly, for high-precision cutting and multi-axis movement, a servo motor is quite effective. In addition, it manages all the cutting accuracy and precision.

2. Acceleration-controls

A servo motor has super-control over the torque and inertia ratio which directly controls the acceleration. Following, it manages the accelerating command over the table or spindle. Accordingly, this ultimately helps in increasing the acceleration and working efficiency.

3. Torque Ripple control

Servo motors maintain the torque ripples during the motor shaft rotation. And, due to rotational fluctuation, it needs deformity-free cutting work, which is controlled by a high-power servo motor in a CNC machine.

4. Uses Encoders

A servo motor uses two types of encodes incremental type and absolute type. Furthermore, both play an important role in the machine’s control. In addition, a CNC machine can record each shaft position via Absolute optical encoders. As well as, it has Gray and binary numerical encoding that controls all the coding activities.

Whereas, Incremental optical encoders help in creating pulse rates and positioning using LED photoemitter-detector pair. Both the encoders are easily adjustable and perfectly mounted for smooth functioning.

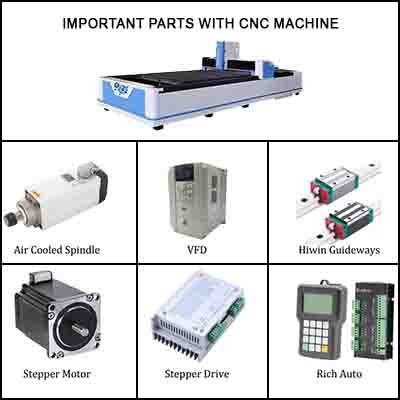

Important Parts-Add-on

| 1. CNC cutting Machine-NC Studio Controller, RichAuto DSP controller, 6.5KW Spindle |

| 2. Air-cooled Spindle- It cools off the heated area using inbuilt fans. |

| 3. VFD- Variable frequency drive controls electric motor |

| 4. Hiwin guideways’ |

| 5. Stepper Motor: It is helpful in single full rotational breakings |

| 6. Stepper Drive: Works by creating electromagnetic fields and motions |

| 7. Rich Auto |

| 8. Servo Brackets: It helps in wiring and mounting of servo motors |

| 9. Feedback Device: A feedback device is used to provide position feedback to the motor controller. |

| 10. Wiring and Cabling: This connects servo motor, motor controller, feedback device, and control system. |

Overall, by going through all the above-shared information. You can get a great overview of multi-application demands and machine requirements. Further, all the parts info shared above will be extremely helpful for the further consideration. Also, you can connect with us by calling/or WhatsApp: 9804718718 to get more ideas.

Frequently Asked Questions

Q1. How is a servo motor helps in prototyping and designing?

A servo motor can rotate up to 360* angle, hence it is helpful in robotics and automation works with high speed and cutting accuracy.

Q2. How is using a servo motor beneficial?

A servo motor is highly efficient, and reliable, has more torque value. Consequently, it can control all the cutting and designing work using the fast and easy-to-go encoder commands.

Q3. What will be the total cost of a CNC router with a Servo motor?

At first, we have the best market price available for both (CNC router +Servo motor). However, for the best-concerned price, you may connect us @Call/or WhatsApp: +91-9804718718