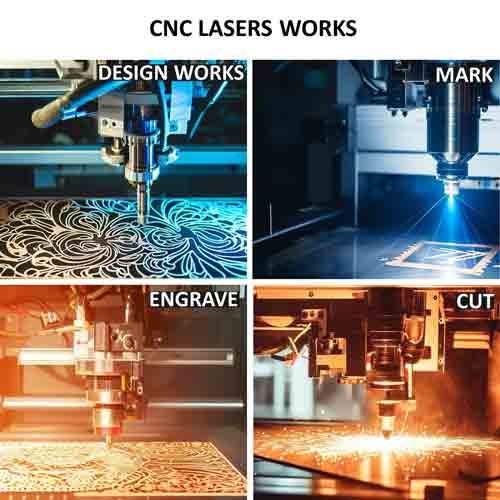

Hindcam deals in two types of laser cutting machines that include a CNC fiber laser cutting machine. A CNC laser cutting machine is used to cut, mark, design, and engrave non-metallic and metallic surfaces using its high-tech CNC computer-controlled software. It includes high-focused laser beam emission that passes through the laser head. A laser head consists of a focusing lens, a laser beam extender, and a nozzle.

CNC Fiber Laser Cutting Machines

A CNC fiber laser cutting machine has advanced technology, which works on laser beam emission technology. Its efficient and high-quality beams are created by a group of diodes that passes through the fiber optic cable. And, the final beam emission category becomes more precise, accurate and the metallic and non-metallic surfaces get high-precision marking, cuttings, and engraving works.

- 1 kw laser cutting machine

- 1.5 kw laser cutting machine

- 2 kw laser cutting machine

- 3 kw laser cutting machine

- 4 kw laser cutting machine

- 6 kw laser cutting machine

- Starting Price: Rs TBD + GST

- Know More: Contact us on 9212300300

So, you can entirely rely on the machine’s output powers(1kw, 1.5kw, and onwards). It includes cutting thickness levels less than 5mm of thickness level. Additionally, here you can get the higher-precision cutting with no contact on the material surfaces. it includes SS sheets, aluminum, copper, brass, etc.

What is the working process of A CNC Laser Cutting Machine?

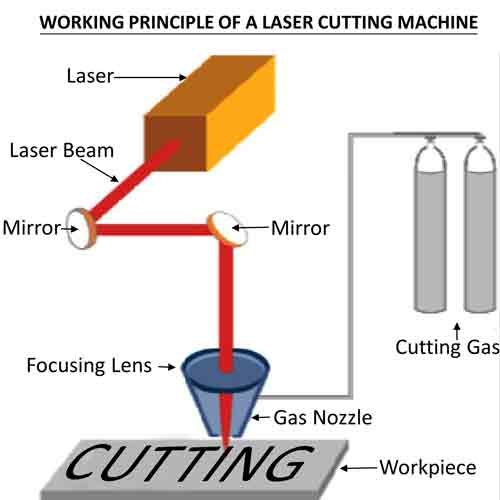

A CNC machine is a high-end automated machine. In addition, it has software to control all the operational activities for cutting, designing, and many others. However, you can also set your program as per your preferences and material category using a fiber laser cutting machine.

Moreover, here you get focused lenses and a well-set nozzle which helps in speculated beam emission over the material surfaces. So that the beam emission transmits over the cutting area and up to the required cutting thickness level.

How is a Fiber laser becoming a high-end choice in industrialization?

Here are a few of the points, which can describe its essential parameters in the world of laser cutting accuracy and precision of works:

- Versatility and Applications: Due to the laser cutting machine, a wide range of materials is cut effortlessly. Further, by using CNC Fiber laser Cutting Machines, you can more efficient results . It includes metals(Aluminum, copper, etc.) and non-metals (woods, acrylics, fabrics, and many more). Explore the diverse industries and applications that benefit from this versatility.

- Automation and Customization: Now, by using the computer numerical control (CNC) capabilities in CNC fiber Laser Cutting Machines. In addition, it allows seamless automation and customization over the machinery and tool for cars, high-end vehicles, and much more. Moreover, intricate designs and complex cuts are becoming easier.

- Global Impact and Industry Adoption: Discover the worldwide impact of CNC fiber Laser Cutting Machines. And their widespread applications needs are acceptable in many industries. Further, it has evoked the uses of laser beam emission for higher cutting accuracy and much more.

- Unleashing Innovation: Showcase the transformative power of CNC fiber Laser Cutting Machines in driving innovation. Explore the limitless possibilities and creative opportunities that arise from incorporating this cutting-edge technology into various fields.

- Future Developments: As, the laser cutting machine has raised the future development of machinery related to high-precision cutting, marking, and designing works. So, it has boosted the final polished material surfaces, and also with less wastage. Moreover, the future scopes of CNC fiber Laser Cutting/Fiber laser cutting Machines and glimpse of upcoming advancements and innovations that will further revolutionize precision cutting is higher.

Why to choose a CNC Fiber Laser Cutting Machine?

A fiber laser cutter or a fiber laser has different operational specifications. And, it helps in precise cutting accuracy and more versatile results in many industries. It includes woodworking industries, construction, outdoor and indoor gadgets, and aviation products and the list is everlasting.

So, here is what benefit you get once you choose a machine. It is enlisted here:

- Best over the refractive materials: The fiber lasers bring quite effective results in cutting of many reflective materials like aluminum, copper, etc. And, without this high-end machinery, it may not be possible to get that perfection over the material surfaces.

- Focused beams quality and flexibility: The beam emission quality is unbeatable and the outcome that you get is remarkably fine.

- Sharpe edges quality: You get sharper and clean edges over the material surfaces and also faster cutting speeds.

- Precise and high-quality cutting works: More precise and high-quality cutting work you get here.

- Cost and time-efficient machine: You get a cost and time-efficient machine that could run for many years without any deformity. So, your one-time initial investment brings fruitful results.

Main CNC laser-cutting Application

The major CNC laser cutting applications include much industrial higher cutting accuracy in aviation, construction, cutting frames, etc. So, here we will be discussing a brief application in many industries:

- Kitchen industries: It includes Kitchen cabinets, doors, windows, and many other decorative and kitchenware products.

- Bricks & Stones: It includes the works like Memorial garden boulders, Stone jewelry, Slate, and brick. flooring floor tiles

- Granites & Marbles: Similarly, a beautiful marks, cuts and engraves using a fiber laser over Flooring tiles, Garden stepping stones, Countertops.

- Hardwood floors: Indoor and outdoor units marking, designing and engraving patterns using a CNC lasers.

- Signage works: The official and home-based signages cutting and designing over metallic and non-metallic surfaces with higher accuracy. It includes Awards and plaques, trophies, etc.

- Jewelry Diversification: Personalized Jewelry marking, cutting, and engraving work over the Gold, silver and other material surface.

- Glass products: Car windows, Mirrors, Tiles, Wine glasses, Beer growlers, Liquor bottles, Fermentation Bottles.

At last, here you can easily justify your needs over metallic and non-metallic surfaces with high-precision cutting quality by investing in a Fiber laser . Also, you can go through to get to know more about its further info @ Call/WhatsApp 9212300300