The technologically advanced laser marking machine has exact batch numbers, batch codes, numbers, dates, packaging dates, expiration dates, and laser marking. It has reduced the trend of thermal inkjet printer marking, as these conventional methods have resulted in waste and material damage. It is recommended to move with a UV laser, fiber laser, and CO2 laser marking machine as per the material category (metal and non-metal ) and marking results proficiency.

Batch coding machine, batch coding using laser

Why is a laser machine better than a thermal inkjet printer for batch coding?

There are many significant reasons why a laser marking machine is a better choice than a conventional thermal inkjet printer.

Thermal inkjet printer: A traditional way of marking via the thermal inkjet printer requires more ink and maintenance every time. Also, it might be possible that it gets jams (with pumps, filters, or tubing) and stops working whenever urgently required. Additionally, it can exploit printing designs due to spilage or any kind of imperfections due to catridge shorts and deformities.

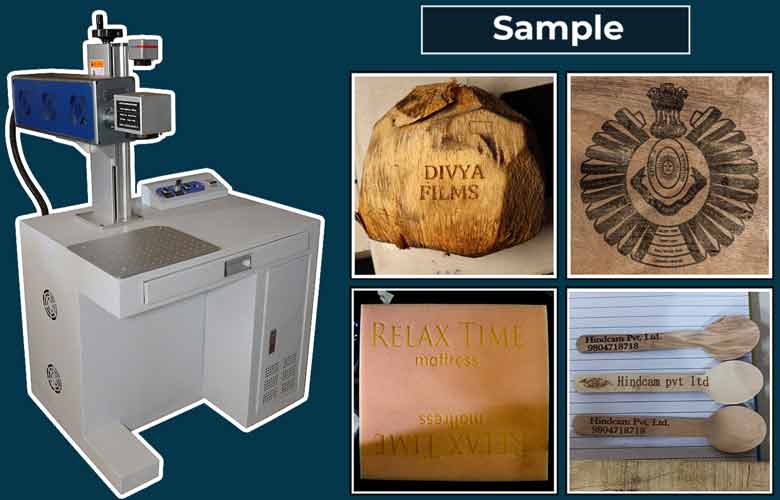

Laser Marking Machine: An automated and upgraded laser marking machine has built-in EZCAD software that not only designs the logo, barcode, batch code, number, etc. But it also marks over non-metal or metal material using its highly efficient laser beam. In addition, it needs minimal maintenance and is very cost- and time-efficient. And, no consumables requirements for the laser printing.

Moreover, you can decide on your marking requirement as per the material. And, it helps in deciding on which laser machine will be a perfect choice(co2, fiber, uv).

Laser marking on samples provided by our client

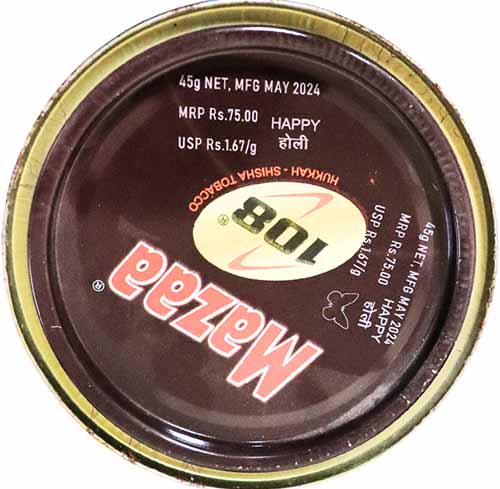

We have got a few of the samples for laser printing, and to know about which one wil be good over the food item box, batch coding, and other sample very precisely and accurately. Here, we have tried the logo creation( sent by customer)on our EzCAD software, and marking over the batch, tobacco box and other samples. The overall batch code marking takes an approximate time of 1.5 seconds.

Finally, you can see the laser work precision of the marking logo, as forworded by our customer. Although, we have tried the laser marking using fiber laser and co2. But the customers requirement got fullfilled using the uv laser marking machine.

Samples via other laser marking machines

Read More

Summary

In conclusion, we have a happy customer with the laser marking samples provided via the UV laser marking machine. However, before purchasing the laser marking machine (UV, fiber, or CO2), we must see the material category and required laser marking machine type with power requirements.