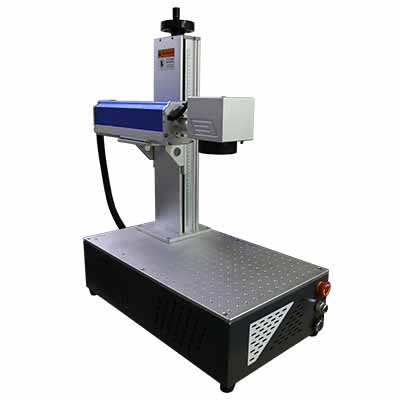

Colorful high-quality and precise markings are done on stainless steel and other metallic surface using a high-tech software machine of MOPA laser marking machine. It has a wavelength of 1064nm for the marking, designing, cutting, and engraving needs. Here, an optical amplifier helps in laser beam emission over the material surfaces and creates appealing designs and marks. So, we shall be discussing here the valuable applications of a MOPA laser.

- Mopa-laser-marking-machine

- Starting price: RS TBD+GST

- Call/WhatsApp: 9212300300

Applications of Mopa Laser

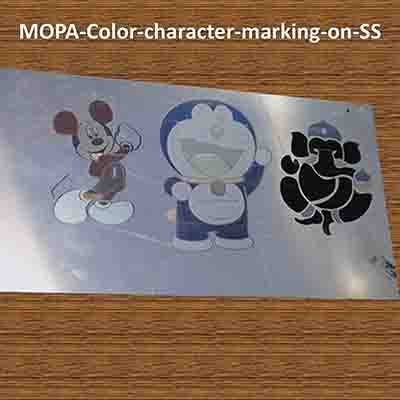

A MOPA laser marking machine has inbuilt EZCAD software. And uses a Galvo head, and F-Theta scanning lenses to mark the specified area over the material surfaces using Double red light positioning. In addition, a MOPA laser marking machine is mostly used for colorful marking over metallic materials, especially stainless steel. Here, are some of the industrial applications of MOPA laser marking machines:

- Manufacturing Industries: For the precise marking on aluminum utensils, color marking on stainless steel, and designing and engraving patterns on different metal sheets. This includes paint removal, laser cleaning, and laser markings on automobiles, aircraft, or household appliances. It works perfectly and on the very specified area on metallic and non-metallic surfaces.

2. Electronics Appliances markings: For accuracy, no contact and precise markings over the electronic items. It includes PCB circuit boards, micro-electronics, Smartphones, PCs, semiconductors, flame-retardant plastics, and many more. So, many gadgets in electronic appliances laser marking done using the MOPA technology of beam emission.

3. Plastic-making industries: A MOPA laser marking machine not only precisely marks over metallic surfaces but also non-metallic surfaces. It includes ID card labeling and marking,

4. Communication and LIDAR Systems: Mopa lasers find application in optical communication systems and LiDAR (Light Detection and Ranging) technology. In LIDAR systems, it is used over autonomous vehicles, environmental monitoring, and surveying departments.

5. Scientific Research: Mopa lasers is valuble in scientific research across various disciplines, including physics, chemistry, and biology. They enable researchers to study and manipulate materials, perform spectroscopy, create high-energy pulses for generating extreme conditions, and conduct experiments that require precise control of laser parameters.

6. Laser Cleaning: Mopa lasers helps in laser cleaning processes to remove contaminants, rust, coatings, and other unwanted substances from surfaces. The adjustable pulse durations enable controlled removal without damaging the underlying material, making it suitable for cleaning delicate surfaces.

7. Medical Applications: Mopa lasers are also very useful in the medical field, including dermatology and ophthalmology. So, whether it is tattoo removal., skin pigmentations, or many other skin-related laser applications. The MOPA laser machines work perfectly.

8. Stainless-steel colourful markings: A Mopa lasers is mostly famous for its appealing color marking over the stainless steel materials. And, in many metallic products making industries, this helps in color markings.

Feature for its worldwide acceptance

- It is widely applicable in a range of materials over metallic and non-metallic.

- The MOPA laser creates permanent, clear, and precise markings over the stainless steel materials.

- It has high-quality beams which are self-adjustable using the auto-CAD commands.

- The machines have a good lifespan and are more durable to work for many years.

- A MOPA laser machine is flexible over a wider range of materials category.

- The flexibility and controllability of pulse parameters make Mopa lasers valuable tools.

- In various industries where precise laser processing, marking, engraving and cuting materials on metallic and non-metallic surfaces needs are there. It is highly recomended to go with a MOPA laser marking machine.

Overall, a MOPA laser is mostly used in vibrant color marking on metal surfaces. In addition, many industries can take a leap in their production unit via the MOPA laser beam emmission technology.

Samples of MOPA lasers on SS sheets