A laser welding machine is capable of doing 3 in 1 working of laser welding, laser cutting and laser cleaning over numerous metal. Here, we shall be going through the mild steel welding(4mm sheet), SS(2mm) welding through nitrogen gas with or without wire feeder.

How it works?

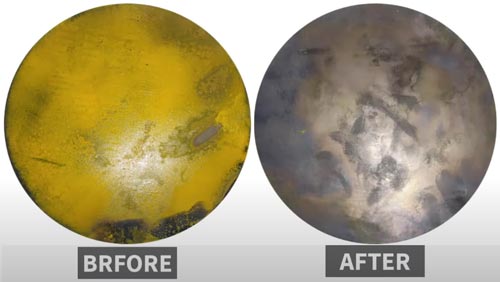

For laser welding perfection, we need to set up the welding parameters in the laser welding system. It includes scan width, scan speed, peak power, duty cycle, frequency, and so on. Next, we can laser weld through the laser gun without a feeder. We have placed mild steel (4 mm) and SS (2 mm) sheets and done welding work. Additionally, we can also remove the rust from the iron and other rust-prone materials. And all higher-quality welding needs can be clearly seen by simply cleaning the surfaces with the cloth.

Samples of welding machine

laser welding

Rust removal

Components of Laser welding machine

3in1 laser welding machine is used for the multipurpose works. It includes laser welding, laser cutting and laser cleaning over the metallic materials. All works are done through the laser gun and different compatible nozzels. Here, we shall be going through the major laser welding machine components that participates in all:

The main components are listed below:

- LASER SOURCE: This is the device that generates the laser beam used in laser welding processes. It provides the coherent light necessary for precise and focused welding.

- WIRE FEEDER: In welding, especially MIG (Metal Inert Gas) welding, a wire feeder is used to feed the welding wire continuously into the welding arc. This wire becomes the filler material that melts and joins the materials being welded.

- WELDING HEAD: This refers to the part of the welding equipment that holds the welding torch or laser head and directs it precisely during the welding process. It can include various components depending on the type of welding being performed.

- WATER CHILLER: Welding processes can generate significant heat, especially in laser welding or high-power welding applications. A water chiller is used to cool the equipment, such as the laser source or other components, to maintain optimal operating temperatures and prevent overheating.

Together, these components form parts of a welding system, each playing a crucial role in ensuring the welding process is efficient, precise, and safe.

Read More

- 1kw laser welding machine

- 1.5 kw laser welding machine

- 2kw laser welding machine

- 3kw laser welding machine

Watch the video

Questions and Answers on this video

Q1. Which gas will run in it?

It runs through Argon gas.

Q2. Is Ms with ss joint possible?

yes possible

Q3. What is the total price with GST?

Full set with all items costs around RS. 525000 +GST. Watch this video for detail about what is included in this price by following: https://youtu.be/CyLbLeNGn2k